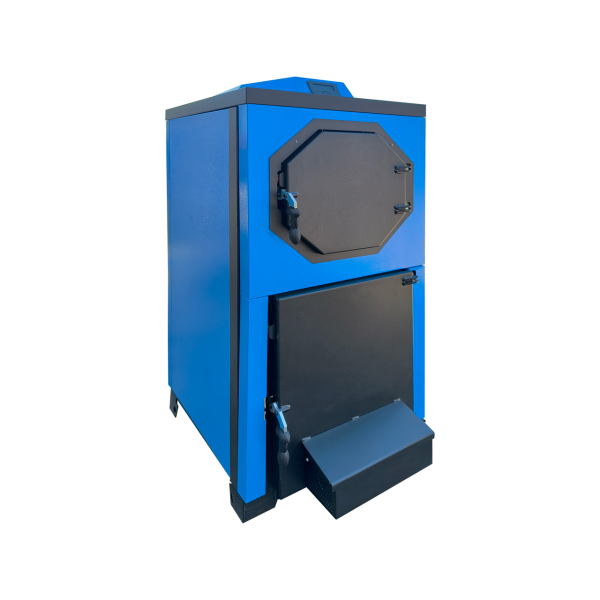

Λεβητας Ξυλου 90kW

→ Στοχεύουμε σε συστήματα θέρμανσης φιλικά προς το περιβάλλον και αποτελεσματικά από πλευράς κόστους.

Ο λέβητας έχει βελτιστοποιηθεί από τον σχεδιασμό. CFD αναλύσεις και οι διάφοροι έλεγχοι, διενεργήθηκαν κατά τη φάση της σχεδίασης και της παραγωγής για την εξασφάλιση υψηλής απόδοσης λειτουργίας. Εξοπλισμένο με αισθητήρα λάμδα, ένα πατενταρισμένο ηλεκτρομαγνητικό κλαπέ και ένα διπλό ανεμιστήρα 15 ταχυτήτων

Με τον φυγοκεντρικό ανεμιστήρα, ο λέβητας ρυθμίζει την παροχή αέρα σε 15 διαφορετικές ταχύτητες, προκειμένου να παρέχει την βέλτιστη ποσότητα οξυγόνου για την καύση. Για την καλύτερη διαχείριση του καύσιμου, υπάρχει ένα ενσωματωμένο υγρασίομετρο και τρία προγράμματα λειτουργίας [ξηρά, κανονικά, υγρά].

Ο θάλαμος καύσης έχει κυματοειδές σχήμα, υδρόψυκτη σχάρα και οι πέντε διαδρομές καυσαερίου που μεγιστοποιούν την επιφάνεια ανταλλαγής θερμότητας. Η υψηλή απόδοση είναι σημαντική, για να κρατάμε τους πελάτες μας ζεστούς με όσο το δυνατόν λιγότερα καύσιμα, εξοικονομώντας χρήματα, αλλά και προστατεύοντας περιβάλλον.

→ Σχεδιάζουμε με γνώμονα την ευκολία χρήσης

Η διευκόλυνση του χρήστη είναι η πρώτη μας προτεραιότητα. Ο λέβητας ξύλου BM έχει μία μεγάλη οκτάγωνη πόρτα τροφοδοσίας που κάνει εύκολο το γέμισμα με μεγάλους κορμούς και ρίζες. Όταν η πόρτα είναι ανοιχτή, το πατενταρισμένο μαγνητικό κλαπε κλείνει, ώστε να περιοριστεί η είσοδος αέρα και τα καυσαέρια να μην ξεφύγουν από την πόρτα τροφοδοσίας. Επιπλέον, είναι ενσωματωμένος και ο έλεγχος 4 αυτονομιών (4 θερμοστάτες και 4 ηλεκτροβάνες).

Όσον αφορά τον καθαρισμό και συντήρηση, είναι ελάχιστη δυνατή. Το μεγάλο δοχείο στάχτης μπορεί να χωρέσει στάχτη ξύλου που παράγεται από 0,5-1,0 τόνο καμένου ξύλου. Οι συμπυκνώσεις και αποθέσεις πίσσας αποφεύγονται με τη διατήρηση του κυκλοφορούντος νερού στο λέβητα σε μια θερμοκρασία υψηλότερη από 63°C.

Παρέχεται, επίσης, ασφάλεια σε περίπτωση έκτακτης ανάγκης. Ο ηλεκτρονικός πίνακας ελέγχου εκτελεί ελέγχους κάθε δευτερόλεπτο. Είναι διαθέσιμη η λειτουργία ασφαλείας, πράγμα που σημαίνει ότι μόλις παρουσιαστεί κάποιο μη σημαντικό πρόβλημα, ο λέβητας μπορεί να εξακολουθεί να λειτουργεί αυτόματα με εναλλακτικό πρόγραμμα. Κατά τη διάρκεια μιας απρόβλεπτης διακοπής ρεύματος, το κατοχυρωμένο με δίπλωμα ευρεσιτεχνίας μαγνητικό καλπε κλείνει τον εισερχόμενο αέρα. Ως αποτέλεσμα, η φωτιά μειώνεται χωρίς να αφαιρέσετε χειροκίνητα το καύσιμο. Σε περίπτωση που ζητούν οι θερμοστάτες αλλά η φωτιά είναι σβηστή, δίνεται εντολή αυτόματα σε μια εναλλακτική πηγή.

Σε περίπτωση υπερθέρμανσης, ο ενσωματωμένος εναλλάκτης ψύξης ενεργοποιείται αυτόματα. Τέλος, η πίεση θραύσης του λέβητα είναι 15 bar.

Σύμφωνα με το πρότυπο κανονισμού EN 303-5: 2012.